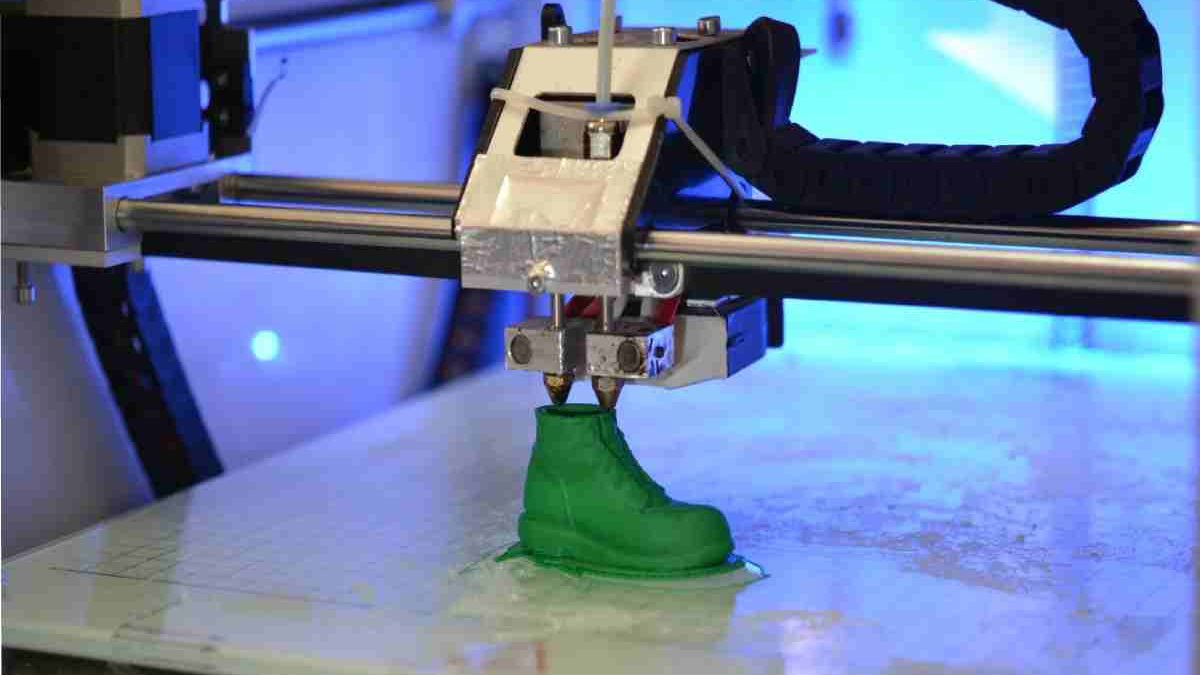

Individual print items may create using 3D printer. For a long time, printers were primarily utilised by industry, for example, to generate low-cost prototypes. They are now great for hobbyists and creative persons who want to make little presents, art pieces, or jewellery. Many questions emerge while dealing with a 3D printer for the first time.

Table of Contents

A Quick Rundown Of the 3D Printer

In 1983, American Chuck Hull created the first printer capable of producing three-dimensional workpieces. Three years later, he submitted a patent for his stereolithography method. Additive developed is the term used to describe 3D printing.

A 3D printer, unlike a traditional printer, does not use ink. The machines make a variety of workpieces out of liquid or solid materials. Among the processing materials are:

- pottery

- sand

- plastics

- metals

Carbon and graphite materials are perfect for 3D carbon component fabrication. The moulding process does not necessitate using any extra equipment or moulds, depending on the 3D printing technique employed.

For Which Applications Are A 3D Printer Suitable?

For a long time, limit the use of 3D printer to industry and research. The process is also suitable for model building. With its help, the individual and comparatively inexpensive production of:

- prototypes

- inspect

- tools

- end products

3D printing is suitable for realising creative decorative objects or jewellery designs in the artistic field. Another area of application is in medical and dental technology.

If companies need a small number of components with high complexity, the manufacturing process remains economical in contrast to classic archetypes.

Due to the fast and individual production options, 3D printer will use in the construction industry. Compact and small devices are ideal for home and entertainment use.

What Is 3D Printing Software Used? (CAD)

Sure 3D printer need the usage of proprietary software. It calls for the use of a slicer and CAD software. The former separates the print item into two-dimensional layers before sending print data to the printer. It shows a high level of compatibility. You may also find online freebies and a variety of standard formats.

Both software packages function in tandem. Slicer programmes prepare an item for 3D printing by slicing it into layers. You create the item using a CAD application for this purpose.

How Does Execution Work In 3D Printing?

Layer by layer, all 3D printer produce items. The print pattern, or 3D model, is required. Downloading a template from an internet database also works.

A 3D printer divides the print object into layers before printing. The term stands for thin, two-dimensional layers. During the processing procedure, the device stacks them on top of each other. It would help if you had the slicing software for this purpose. With their help, it is likely to transfer object data and specifications for working speed or dimensions to the machine. Depending on the model you use:

- memory card

- WIRELESS INTERNET ACCESS

- USB stick

- USB cable

With resin or DLP printers, liquid resin applied in layers hardens under UV light. In the software, you decide how to print your print object:

- solid

- semi-solid

3D Printer

With most 3D printing processes, you expect a lot of time. On average, the process takes several hours. If the printed object measures a few centimetres, it takes one to four hours to complete. A 3D printer works for one to two days to realise large projects.

In addition to the dimensions of your project, various factors influence the printing time. These include the print resolution and the materials used. With the resin printing process, the height of your print object affects the duration. Length, width, or number play an equal role with the FDM printer.

FDM printing is suitable for larger print objects. The method is convincing due to its widespread use and comparatively lower costs.

The corresponding printers work with a layer thickness between 0.1 and 0.4 millimetres. After the cooling phase, the 3D printed products can be fully load. You will receive the resin printer pre-assembled. DLP printers create objects with a layer thickness between 0.01 and 0.05 millimetres.

They work more precisely than FDM printers. Compared to the FDM variant, they are associated with a higher workload. After the printing process, the printed objects must be cleaned and cured.

What Projects Does 3D Printing Enable?

A 3D printer enables the printing of household items such as toys, crockery or decorative items. Jewellery and accessories also come from the printers for home use.

In addition to small objects, 3D printer print large objects. In 2016, the process resulted in the first house. It will make the Chinese company Huashang Tengda. 3D printerare now being use in Germany to construct prefabricat homes. For this purpose, they pile up special concrete to house walls. In comparison to classic house construction, the 3D products are convincing with:

- low workload

- fewer construction costs

- higher sustainability

- Frequently asked questions about 3D printer

To realise projects with the resin printer, you also need spatulas and tools to align the printing platform. In addition, the use of DLP printers requires protective equipment such as disposable gloves and a breathing mask.